Eriez Video Reveals Best Practices for Hopper Transitions in Vibratory Feeders

Eriez®, a global leader in material handling technology, has released a new educational video highlighting the importance of hopper transition design in optimizing vibratory feeding and conveying systems. The video provides actionable guidance on proven design techniques that enhance material flow and maximize feeder efficiency.

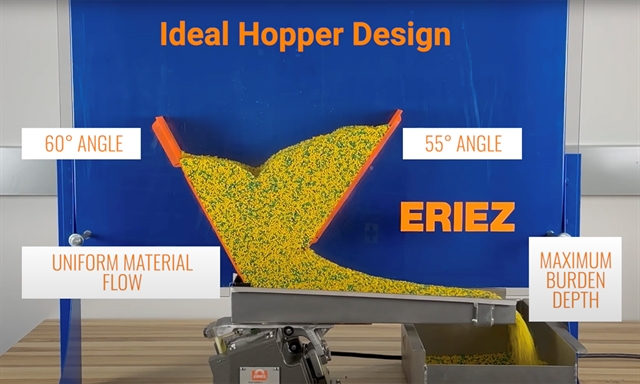

The video walks viewers through the fundamentals of ideal hopper configurations, demonstrating how proper transition design ensures uniform material flow, maximizes discharge depth, and reduces excessive load on the feeder tray. It also describes the negative impacts of common design mistakes, such as flat or vertical hopper walls and oversized throat openings, which can lead to material buildup, flow restrictions, and diminished feeder capacity.

“Even subtle issues in hopper design can have significant consequences,” says Clay O’Dana, Eriez Global Product Manager–Vibratory. “From material buildup and flow restrictions to reduced feeder capacity and increased equipment size requirements, poor transitions lead to costly inefficiencies.”

Key topics include:

- Hopper transition design considerations for vibratory feeding and conveying

- Hopper geometry for maximum material flow

- Common design flaws and subsequent impact on flow patterns and feeder load

- Practical tips for achieving consistent, reliable bulk material handling performance

The video emphasizes that hopper performance varies based on material characteristics, and each application requires careful consideration of these variables to achieve optimal results.

To watch the new Eriez hopper transitions video on YouTube. For more information about Eriez Vibratory Feeders and Conveyors.